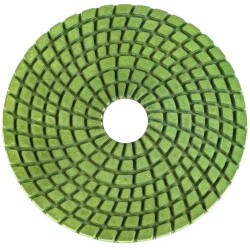

Granit elmas çanak taşlama, granit gibi sert ve aşındırıcı malzemeleri şekillendirmek, düzleştirmek ve parlatmak için tasarlanmış özel bir alettir. Beton için kullanılan çanak taşlamalara benzer olsalar da, granit ve diğer doğal taşların özelliklerine göre farklılık gösterirler.

Granit Elmas Çanak Taşlamanın Özellikleri

Granit, sertliği ve yoğunluğu yüksek bir malzemedir. Bu nedenle, onu işlemek için kullanılan araçların da son derece dayanıklı ve etkili olması gerekir. Granit elmas çanak taşlamaların ana özellikleri şunlardır:

Elmas Segmentlerin Kalitesi: Graniti kesebilmek için kullanılan elmas segmentlerin kalitesi ve sertliği çok yüksektir. Bu segmentler, granit matrisinin özelliklerine uyum sağlamak üzere tasarlanır.

Bağlayıcı Matris: Granit için tasarlanmış çanak taşlamaların metal bağlayıcıları, genellikle granitin aşındırıcı özelliklerine dayanacak şekilde sertleştirilmiş özel alaşımlardan oluşur. Bu, elmasların doğru oranda açığa çıkmasını ve verimli bir şekilde kesim yapmasını sağlar.

Segment Sayısı ve Şekli: Granit için üretilen çanak taşlamalar, yüzeyde daha pürüzsüz bir bitiş sağlamak üzere daha fazla segmente sahip olabilir. Ayrıca, daha az ısı üretmek ve malzemenin çatlamasını önlemek için özel olarak tasarlanmış segment şekilleri de kullanılabilir.

Islak veya Kuru Kullanım: Birçok granit çanak taşlama, hem ıslak hem de kuru kullanım için uygundur. Islak taşlama, tozu kontrol etmeye, sürtünme ısısını düşürmeye ve diskin ömrünü uzatmaya yardımcı olur.

Kullanım Alanları

Granit elmas çanak taşlama diskleri, özellikle taş işleme endüstrisinde ve inşaat sektöründe yaygın olarak kullanılır:

Granit Plaka ve Tezgah Yüzeylerinin Düzeltilmesi: Granit levhaların yüzeyindeki düzensizlikleri gidermek ve onları daha pürüzsüz hale getirmek.

Kenar Şekillendirme ve Profilleme: Granit mutfak tezgahları, mezar taşları veya döşeme taşlarının kenarlarını yuvarlamak veya istenen profilde şekillendirmek.

Kesim Sonrası Pürüz Giderme: Bir granit levha kesildikten sonra kalan pürüzlü kenarları temizlemek ve düzleştirmek.

Restorasyon: Eski granit yüzeylerdeki lekeleri, çizikleri veya kusurları gidermek.

Güvenlik ve Önemli Notlar

Granit elmas çanak taşlama aletleri de yüksek devirde çalıştığı için güvenlik önlemlerine riayet etmek hayati önem taşır:

Kişisel Koruyucu Donanım (KKD): İş güvenliği gözlüğü, toz maskesi (granit tozu çok incedir), kulak koruyucu ve eldiven kullanın. Silika tozu içeren granit tozu, solunduğunda ciddi sağlık sorunlarına yol açabilir.

Doğru Devir Hızı: Kullanacağınız aletin devir hızının, taşlama diskinin maksimum hız limitiyle uyumlu olduğundan emin olun.

Soğutma: Mümkünse, ısı oluşumunu önlemek ve malzeme çatlamasını engellemek için ıslak taşlama yöntemini kullanın.

Sınırlı Basınç: Alete aşırı basınç uygulamaktan kaçının. Doğru disk ve devir hızıyla alet kendi işini yapacaktır.

Doğru granit elmas çanak taşlama diskini seçmek, granitin sertliği, taşlama makinenizin gücü ve yapmak istediğiniz işin türüne bağlıdır. Her zaman, belirli bir malzeme için tasarlanmış doğru aracı kullanmak, hem daha iyi sonuçlar almanızı hem de güvenliğinizi sağlamanızı garanti eder.